PRODUCTS

Menu

64R0M-Surface Hand Socket (Manual)- 3/4″ Drive

SURFACE DRIVE HAND SOCKET- 3/4″ DRIVE (MANUAL)

- vasos de surface drive

- statki z napędem powierzchniowym

- Oberflächenantriebsschiffe

- buques de superficie

- سفن محرك السطح

- เรือขับเคลื่อนพื้นผิว

- 大R角手動套筒

- DIN 3120, ISO 1174

- MS 33787, MIL-W-8982

Feature

- Surface Drive sockets are designed to ensure that contact is not lost between the socket and the flat surfaces of the nut when it most matters: when you’re trying to apply maximum torque (and turn off the engine). Since they were first developed, they have been further refined by removing their protruding stem, lowering their profile even more.

- Compared to a flat drive, surface drives make contact with the nut at the center of the bolt, reducing damage and boosting efficiency. Surface drives are also useful for painted face nuts or any nut made of soft material, as well as bolts or nuts that have been damaged by corrosion or wear and tear.

- Compared to traditional Torx® and square head bolts, Hex Cap Screws are bigger and easier to handle. They are also more cost-effective, with the ability to hold most of the jobs it is assigned.

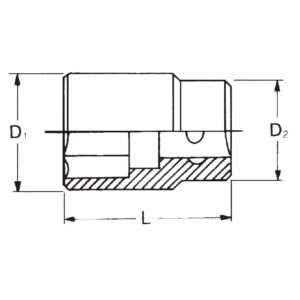

64R0M SURFACE DRIVE SOCKET

| 64R0M (mm) | D1 (mm) | D2 (mm) | L (mm) | g | pcs |

|---|---|---|---|---|---|

| 17 | 28 | 36 | 49.5 | 270 | 5 |

| 19 | 30 | 36 | 49.5 | 280 | 5 |

| 21 | 32 | 36 | 49.5 | 280 | 5 |

| 22 | 33 | 36 | 49.5 | 290 | 5 |

| 23 | 34 | 36 | 49.5 | 300 | 5 |

| 24 | 35 | 36 | 49.5 | 300 | 5 |

| 25 | 36 | 36 | 50 | 310 | 5 |

| 26 | 37 | 36 | 50 | 320 | 5 |

| 27 | 38 | 36 | 52 | 330 | 5 |

| 28 | 39 | 36 | 52 | 330 | 5 |

| 29 | 40 | 38 | 52 | 340 | 5 |

| 30 | 42 | 38 | 54 | 370 | 5 |

| 32 | 44 | 38 | 56 | 420 | 5 |

| 33 | 46 | 38 | 56 | 440 | 5 |

| 34 | 46 | 38 | 58 | 470 | 5 |

| 35 | 48 | 42 | 58 | 490 | 5 |

| 36 | 50 | 42 | 58 | 510 | 5 |

| 38 | 52 | 45 | 60 | 550 | 5 |

| 40 | 56 | 45 | 64 | 580 | 5 |

| 41 | 56 | 45 | 64 | 590 | 5 |

| 42 | 56 | 45 | 64 | 600 | 5 |

| 46 | 62 | 48 | 68 | 730 | 1 |

| 48 | 65 | 48 | 71 | 770 | 1 |

| 50 | 68 | 48 | 72 | 790 | 1 |

Dimension

Profile of SURFACE DRIVE SOCKET

The Drive socket makes use of an innovative design that results in almost twice the contact of a standard flat-topped socket. This helps it transmit more torque at a fraction of the weight and cost. Additionally, this new design also helps protect against rounding of fasteners caused by repeated use of conventional sockets, helping you save on overall maintenance costs.

RELATED PRODUCTS

Related products

-

氣動套筒 Impact Socket-1/2"DR.

84404 Impact Socket- Super Thin Wall- 1/2″ Drive

Rated 0 out of 5Read more -

套筒 棘輪扳手 及套裝Socket / Ratchet / Combo (Socket Wrench Set)

2402M/A- 1/4″Drive Hand Socket (Manual) /12 Point

Rated 0 out of 5Read more -

套筒 棘輪扳手 及套裝Socket / Ratchet / Combo (Socket Wrench Set)

4300M/A-Deep Hand Socket 1/2″Drive- 6 Point

Rated 0 out of 5Read more